InUse : What if your machines could talk ?

InUse: in summary

InUse is a connected maintenance software that makes industrial machines talk to improve maintenance operations.

Turn your industrial data into action for your operators

Firmly oriented towards smart maintenance, InUse transforms connected data of industrial equipment into operational recommendations for operators in factories. By digitizing the know-how of technicians and production experts within the application, InUse gives a new intelligence to industrial equipment. It makes them able to request the maintenance operations they need and guide operators to the best action to achieve according to the production context.

How the industrial maintenance software InUse works

InUse is an online software (SaaS) that collects data from industrial machines in order to analyze them and set up maintenance actions according to the production context. InUse can connect to machines via a PLC (and a gateway if necessary), an IoT platform or any other data collecting system to allow immediate access to your data in the Studio.

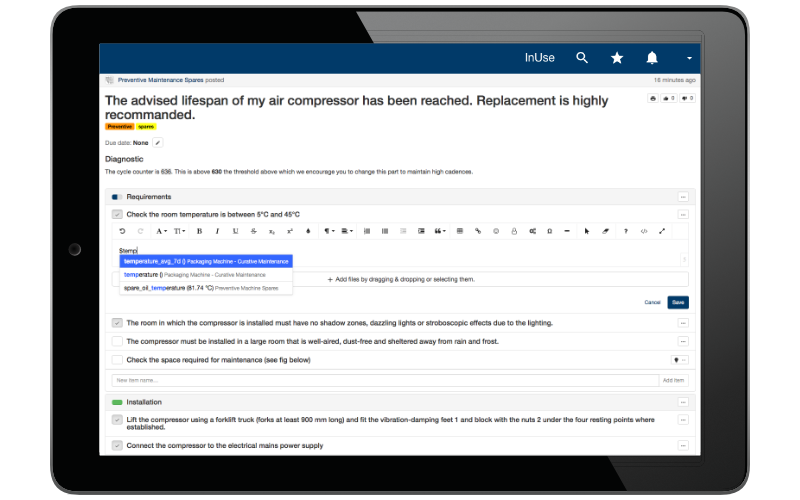

The Studio is the place where machine intelligence is created. It allows first of all to visualize technical data (temperature, duration of actions, failures, etc.) on time series but also to correlate these data and thus create maintenance algorithms. Designed on the basis of mathematical logics and shop floor knowledge of machines (wear, sequence of failures, etc.), they require no code skills to be realized. These algorithms, of which the manufacturer remains in control, make it possible to anticipate the failures and to interpret them correctly when they occur. It is also in the Studio that the messages of the machines which will be communicated to the operators on the shop floor are defined. They can be enriched with concrete instructions to facilitate the accomplishment of the recommended task: display of checklists, procedures and associated documents

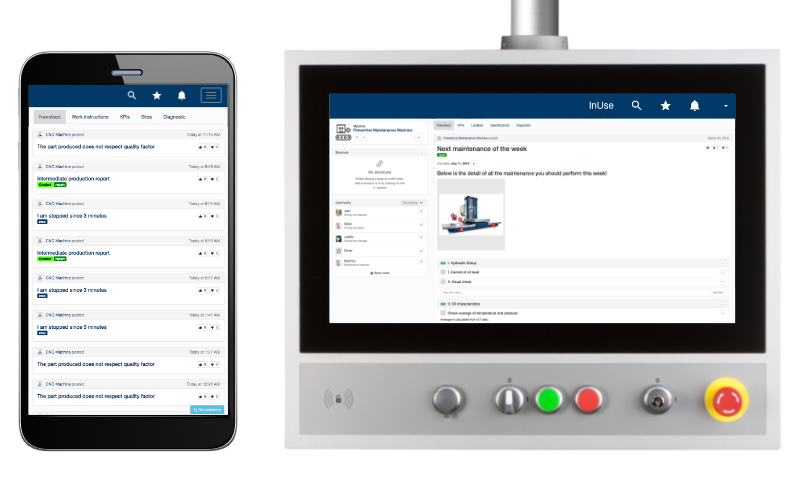

On a day-to-day basis, operators will take full advantage of the Share collaborative platform to share information in real-time in the manner of a social network: posts, discussion thread, checklist, assignment of tasks, note taking, digital maintenance reports, etc. The most of the Share is to integrate machine notifications ("maintenance in 10 minutes", "advanced wear on part C", etc.) and to be accessible on any terminal (tablet, smartphone, HMI, Industrial PC, ...). The team retains full control of the industrial machinery fleet, regardless of their number and complexity.

Easily deploy your connected maintenance services in the factory

Designed to deliver connected maintenance services in the factories, InUse augments the production team of a collective intelligence to significantly improve the industrial production performance. It allows them for example to:

predict future failures of industrial equipment (predictive maintenance)

significantly reduce the time to restart the equipment after a production stop (curative maintenance)

optimize maintenance plans and the dispatch of maintenance teams according to the real usage of the equipment (preventive maintenance)

monitor the evolution of the Overall Equipment Efficiency (OEE)

- implement connected services specific to their activity such as traceability, cleaning in place, etc.

Designing these connected services does not require programming skills: modeling of machine data and correlations is done simply by means of logical expressions. InUse offers intuitive visualization of industrial data as a time series and natively integrates more than 60 operators to create algorithms with ease.

No need to connect your machines to reveal the value of your industrial data

While connecting machines is an essential prerequisite in IoT projects, InUse offers to analyze your historical industrial data to evaluate the potential benefits of your new connected services.

InUse is designed by Paris-based OptimData, part of the Alliance for the Future Industry and French Fab. Its clients include Shem (Engie), Sidel, Alfi Technologies, Olympus Dairy and ICE Water Treatment.

Its benefits

ISO 27001, PCI-DSS

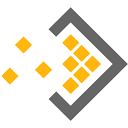

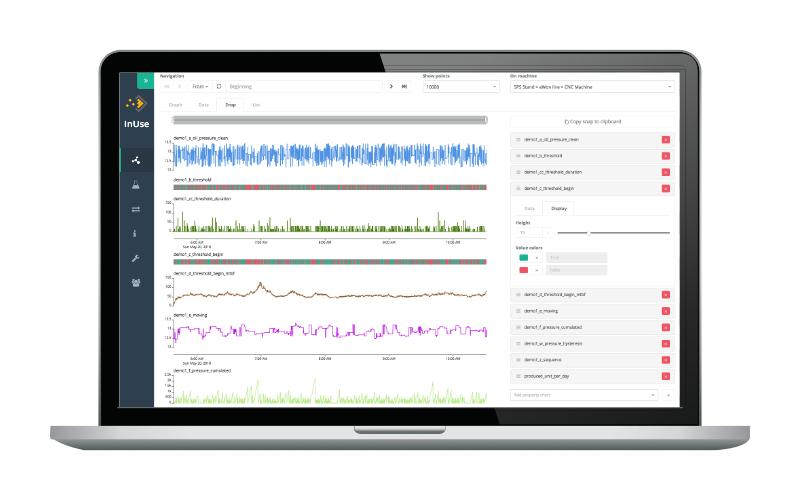

InUse - Visualize your time series of industrial data in the Studio

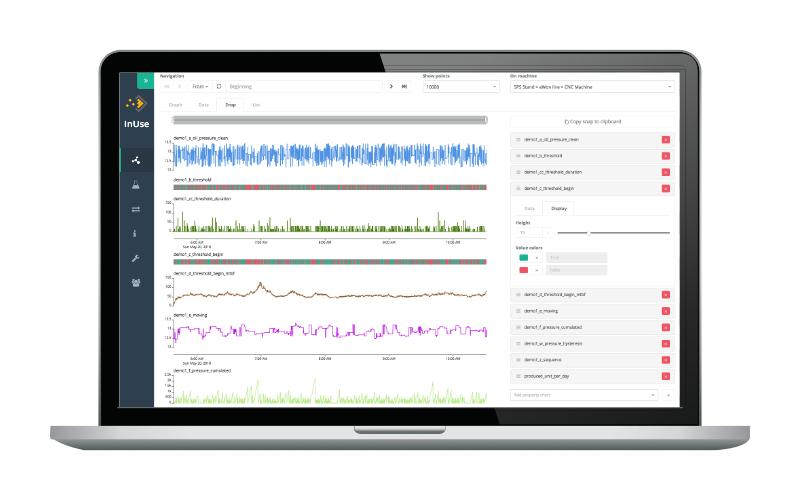

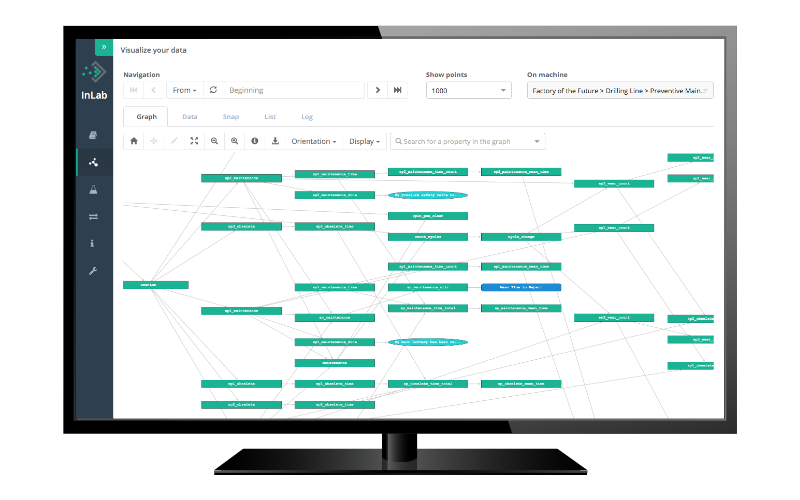

InUse - Visualize your time series of industrial data in the Studio  InUse - Easily create your own algorithms to trigger real-time recommendations on the ground.

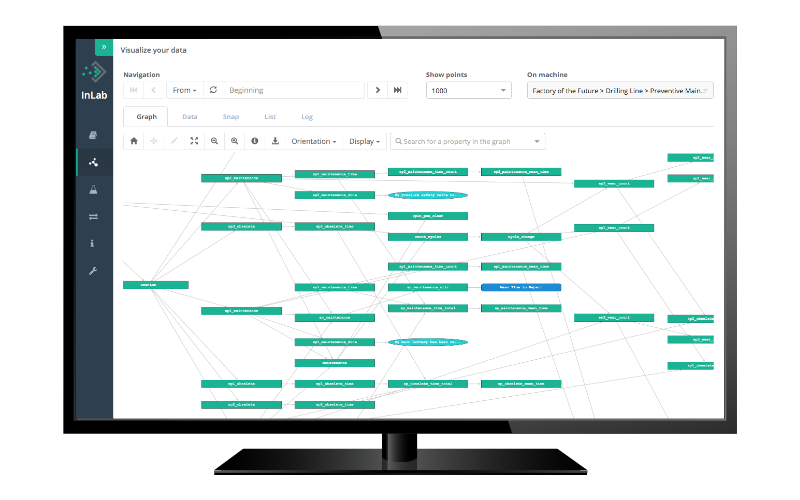

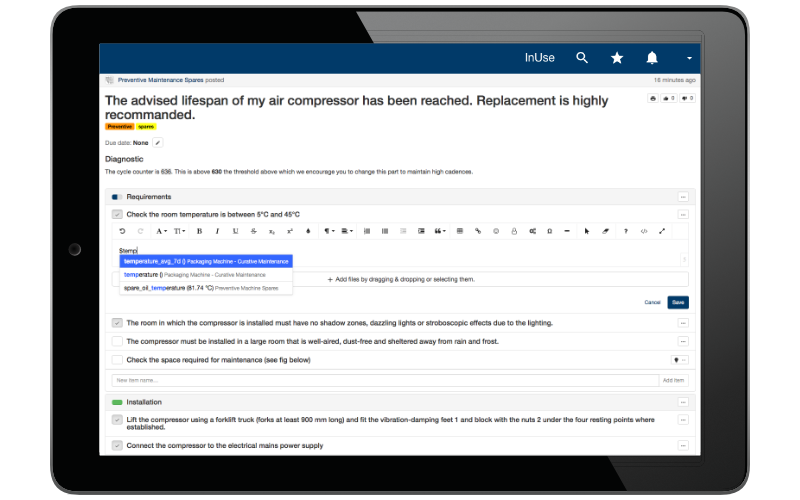

InUse - Easily create your own algorithms to trigger real-time recommendations on the ground.  InUse - Suggest your factory teams the actions to be taken on and guide them with checklists and documentation.

InUse - Suggest your factory teams the actions to be taken on and guide them with checklists and documentation.  InUse - Accelerate editing maintenance records of your teams by automatically incorporating real-time data.

InUse - Accelerate editing maintenance records of your teams by automatically incorporating real-time data.

InUse: its rates

Standard

Rate

On demand

Clients alternatives to InUse

Unlock insights from your data with a predictive analytics software that delivers accurate forecasts and identifies trends in real-time.

See more details See less details

Optimprocess provides a powerful suite of tools that enable you to make data-driven decisions. With features like data visualization, machine learning, and forecasting, you can quickly and easily uncover patterns and trends that would otherwise be hidden.

Read our analysis about OptimprocessTo Optimprocess product page

Predictive Analytics software that helps you make data-driven decisions. Analyze trends and patterns to predict outcomes, and get actionable insights.

See more details See less details

"TechTarget's Predictive Analytics software uses machine learning algorithms to analyze large datasets and identify patterns that can help you make better decisions. With real-time data visualization and customizable dashboards, you can easily identify trends and outliers, and drill down into specific areas of interest.

Read our analysis about TechTargetTo TechTarget product page

Advanced predictive analytics software for businesses seeking to optimize sales and marketing strategies by analyzing customer data.

See more details See less details

Offers a wide range of features including real-time data analysis, personalized insights, and predictive modeling to help businesses better understand their customers and make data-driven decisions. The software is easy to use and customizable, with the ability to integrate with existing systems for seamless implementation.

Read our analysis about Lattice EnginesTo Lattice Engines product page

Appvizer Community Reviews (0) The reviews left on Appvizer are verified by our team to ensure the authenticity of their submitters.

Write a review No reviews, be the first to submit yours.